Choosing the Best Method for Sewer Rehabilitation

With limited funding and stringent compliance requirements, it’s challenging to maintain wastewater collection systems. Communities across the Midwest and beyond face these evolving demands with aging sanitary sewer infrastructure. Due to this situation, many municipalities are investigating techniques for extending the life of their collection system assets through pipe rehabilitation.

The first step in the rehabilitation process is determining the purpose, which begins with answering the following questions. These answers will assist in directing the process toward the most cost-effective, efficient use of resources.

- Does the collection system need structural repair?

- Is infiltration/inflow (I/I) elimination needed?

- Does system capacity need improvement?

- Or a combination?

Common Causes of Sewer System Deterioration

The cause of sewer system deterioration ranges from structural fatigue to general damage, chemical corrosion, old age, and other issues. Knowledge of what’s causing sewer pipes to go bad helps guide informed decision-making for rehabilitation. Outlined below are the four top causes of sewer system damage and deterioration.

Pipeline Structural Fatigue

- Traffic loading

- Freeze/thaw cycle

- Soil Movement

- Erosion or Cavitation

Pipe Corrosion

- Hydrogen Sulfide (H2S)

- Microbially Induced Corrosion (MIC)

Broken & Damage Pipes

- Installation error

- Break-in taps

- Adjacent Construction

- Cleaning

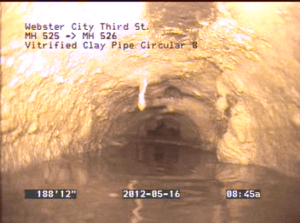

Aging Pipe Infrastructure & Additional Issues

- Material decay

- Stray electric currents

- Organic/inorganic deposits

- Root intrusion

Depending on the severity of deterioration or defect and the type of rehabilitation used, Farrand says the design life of a pipe can often be extended up to 50 years.

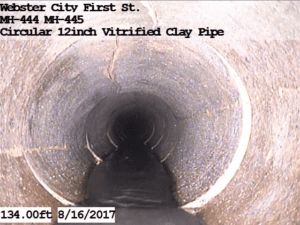

Sanitary Sewer System Evaluations & Inspections

To ensure the smooth operation and maintenance of your sewer collection system, evaluating current conditions with a focus on sewer mains, manholes, laterals, and pump stations is essential.

“A sewer system evaluation is the first step of proactive sewer system maintenance and repair,” states Farrand. “It allows a community to address issues early on before they lead to bigger problems that are more expensive to fix.”

For Wes and his colleagues, sanitary sewer system evaluations are also helpful in determining which rehabilitation techniques are optimal for a given set of circumstances. With the purpose of rehab defined, a plan to address the most critical issues first can be developed and implemented in phases to maximize the use of available funds.

Sewer system evaluations use various methods of inspection or televising with a camera or other technology to provide a glimpse of what’s going on within a sanitary sewer system. Using the NAASCO Pipeline Assessment Certification Program (PACP), the industry standard for coding on system conditions and defects helps maintain evaluation consistency over time.

Inspection Techniques for Sewer Systems

Acoustic Blockage Detection (Sewer Line-Rapid Assessment Tool or SL-RAT)

Fat, oil, and grease buildup in sewer pipes can contribute to sewer pipe deterioration.

Acoustic blockage detection can be a cost-effective way to get a preliminary report on the condition of your sanitary sewer system. Using an acoustic transmitter and signal receiver, sound waves are sent through sewer pipes rapidly to gather information on pipe conditions.

While it doesn’t pick up minor defects or provide information on the specific type of issue present in a pipe, it does help determine potential areas of concern for further inspection.

“It’s a relatively new, quick, and easy-to-use technology worth considering, especially if funding is limited,” Farrand says.

Lateral Pipe Inspection

Televising equipment that extends a second camera up lateral services from the main sewer to evaluate the condition of service lines is also available. Service laterals can be a significant source of infiltration that can quickly go unnoticed or unaddressed in rehabilitation plans.

Multi-Sensor Inspection (MSI)

For larger collection systems such as the Des Moines Metro’s WRA Fourmile Creek Sewer Interceptor, MSI is advantageous for instances where higher flows prevent televising using standard crawler-based equipment. By floating through a sewer pipe, MSI gathers HDTV, laser, and sonar data on system conditions.

“Sonar provides information on debris located below the water level. The laser will tell you if there’s voids or corrosion above the water level, and the camera provides a high-definition visual inside the pipe,” he explains.

Prioritizing Sewer System Rehabilitation

Armed with knowledge of current sewer system conditions, the next step is to establish goals for rehabilitation. Naturally, severe defects or deterioration should take priority over less serious issues. However, it’s important to remember that there could be more than what meets the eye.

“Whether your goal is to repair structural damage, reduce I/I [inflow and infiltration], improve capacity, or a combination of everything, you’ll want to review all system concerns carefully,” notes Farrand. “Minor defects can lead to much bigger problems, and things can escalate quickly.”

Sanitary Sewer Rehabilitation Methods

Sewer rehabilitation can take many forms, depending on the cause of deterioration or defect, the severity of the issues observed, the available budget, and other aspects. “Selecting the correct way to rehabilitate your sewer system requires careful thought and analysis,” shares Farrand. “Will service interruptions be required? What’s your budget? What kind of access do we have to the area of concern? You’ll want to address these questions before moving forward.”

Constant innovation within the industry has led to an extensive array of sanitary sewer rehabilitation techniques. Working with a skilled team of professionals will help guide informed decisions for successful sewer rehab. Some common tried and proper methods of sewer rehab to consider include:

Chemical Grouting

Using a chemical grout for sanitary sewer system rehab is a relatively low-cost option with great flexibility, making it applicable in many situations.

“Because it’s a chemical grout, there’s a tremendous amount of variability in the different chemicals that can be used to solve different issues depending on the desired result,” explains Farrand. “There are grouts set in five seconds and others set in 12 hours. Some like water, and some don’t. It all depends on the needs and goals of each unique situation.”

Acrylamide and polyurethane grout are just two of many grout variations and types. Working with an experienced professional is essential to select the appropriate grout for your specific sewer system issues.

Ideal grout applications include open joints, small holes, leaks, I/I reduction, manholes, and lateral infiltration. Grouting can also work well with other rehabilitation methods that provide structural improvements, which grout can’t on its own. The effectiveness of grout can be limited for lateral cracking, large voids, or areas with continuing soil movement. With the proper application and the correct grout, the average service life expectancy of chemical grouting for sewer system rehabilitation can be 20-25 years.

Cured-in-Place-Pipe (CIPP) Lining

CIPP lining has been around since the 70s and has become a standard sanitary sewer pipe rehabilitation method. It utilizes a textile liner impregnated with liquid resin before being inverted into an existing pipe with air pressure. Next, steam or hot water is used to cure the liner, creating a new, corrosion-resistant pipe wall with an expected service life of 50 years.

Minor to moderate structural defects, offsets, protrusions, cracks, root intrusions, and some I/I reduction is optimal for CIPP lining applications. However, if water is seeping in at a service tap, CIPP lining won’t effectively reduce I/I due to the opening made in the liner at the service tap location. Regarding I/I, CIPP lining is better suited for addressing issues with joints and cracks. Depending on system conditions, grouting or root removal may be necessary before CIPP lining can occur.

Additional considerations to keep in mind for CIPP lining include:

- Adding end seals at manholes to prevent water traveling between the old pipe and new pipe from entering structures

- Pre-lining work may be necessary to stop heavy infiltration

- Service taps will need to be reopened

- Future service taps should connect to the liner, not the host pipe

- Lateral I/I requires additional rehabilitation methods

- Curing methods can make a difference

- Uncommon chemicals in sewer flows can affect the liner-curing process

CIPP Point Repair

Using similar technology as CIPP lining, CIPP point repair corrects a single defect in an otherwise structurally sound pipe. However, if more than two point repairs need to be made in the same sewer line, Farrand says it’s often more cost-effective to line the entire pipe.

Less Common Methods to Consider

Other methods of sanitary sewer system rehabilitation that are less common or rarely used but applicable to unique circumstances include:

- Sliplining

- Pipe Bursting

- Centrifugally Cast Mortar Lining

- Other Cementitious Coatings

- Polymer Coatings

- Fold & Form

- Pipe Eating

- Spiral Wound Sliplining

Infrastructure Data Management

Regardless of the methods used to evaluate, maintain, and repair your sewer system, Farrand says keeping records up-to-date and ongoing monitoring of your sanitary sewer system is paramount.

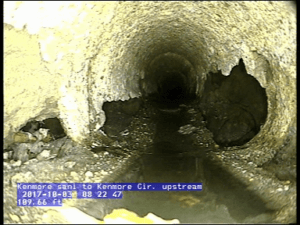

Severe corrosion beyond the capabilities of sewer system rehabilitation can be avoided with regular monitoring.

He encourages communities to get paper copies of any sewer system evaluation report along with copies of any video or photos taken during the evaluation. Providing duplicate records of everything to public works staff, city hall, and city engineers helps ensure data is available when needed. However, as more communities move away from traditional record-keeping systems in favor of electronic record-keeping, geographic information systems (GIS) and asset management systems are quickly becoming the norm.

“GIS and asset management systems take record keeping to the next level by linking and logging data in one central location,” states Farrand. “There’s a lot you can do with GIS, and it’s scalable for each community.”

How often ongoing monitoring and inspection should be done depends on the client, system, and community budget. Some suggest televising every five to seven years, but Farrand feels every ten years can be sufficient with limited budgets.

“It depends on your system. If you have a lot of issues, you’ll need to monitor more often,” he shares. “Older systems should be watched more closely than newer ones, and in some instances, only a portion of your system may need to be monitored more frequently.”

Prioritization for a Proactive Sewer Maintenance

Sewer system rehabilitation can be overwhelming, especially as financial resources become increasingly strained. However, through proper planning and ongoing monitoring, restoration remains a highly cost-effective way to maintain sewer system infrastructure long-term.

“The best way to avoid costly repairs and service interruptions is to put a proactive plan of action in place. Taking a proactive approach allows us to phase the monetary burden of rehabilitation to fit within a community’s annual operating budget,” he says. “In the end, unaddressed, deteriorating pipes create bigger problems and ultimately cost more money.”