Foreseeable Strategy to Increasing Regulations

The industrial segment is directly impacted by shifts in the U.S. political climate. This requires a forward-looking strategy to anticipate how potential regulation changes may affect development and operations. Regulations provide environmental protections, but they can also produce challenges in productivity and profitability. Effluent regulation can be one of the biggest obstacles to overcome. Limits are tight regardless of approval type. Clients that are full effluent dischargers and clients who make use of pre-treatment have the same restrictions, flow limits, constituent limits and more.

Listen in as our expert Environmental Scientist, Jeff Walters, PWS, hosts Darin Jacobs, P.E., to discuss key industry trends in environmental regulations. During this podcast episode, they discuss industry issues, common hurdles such as financial independence when meeting limits and lack of guidance from state, client support such as getting familiar with them and their facilities, predictions on future industry trends, and supply insights on design, engineering, and construction services.

Podcast Agenda

- Regulation Limits for Wastewater (0:18)

- Pre-Treatment vs. Full Effluent Discharge Permitting (1:04)

- Environmental Hurdles for Industrial Permitting (2:20)

- Financial Assistance (3:43)

- Assisting Industrial Clients (5:26)

- Permitting for Industrial Projects (10:37)

- Foreseeable Industry Trends (14:33)

Jeff Walters, PWS

Environmental Sciences Work Group LeaderJeff Walters, PWS

Environmental Sciences Work Group LeaderWetland & Stream Delineation & Mitigation, 404 Permitting, Natural Resources Surveys, Lake & Stream Restoration

Darin Jacobs, P.E.

Water Resources Work Group LeaderDarin Jacobs, P.E.

Water Resources Work Group LeaderMunicipal Water & Wastewater Planning, Water Quality Modeling, Railroad Design & Construction

Stringent Effluent Regulation Limits for Wastewater

Jeff Walters (0:18)

Darin, what are your biggest industry issues pertaining to environmental regulation these days?

Darin Jacobs (0:26)

I would say at this point in general, it’s tighter and tighter effluent regulation limits on wastewater. Whether the industry is discharging with its own wastewater treatment plant and holding its own NPDES permit or if they are actually just doing pre-treatment and then running through a municipal treatment system for final effluent.

Jeff Walters (0:52)

Where do you think your clients would like to be in the realm of being a pre-treatment or a full effluent discharger? Is there a big difference that our clients prefer?

Pre-Treatment vs. Full Effluent Discharge Permitting

Darin Jacobs (1:04)

I don’t know if there is a preference really. Either way, you have to meet certain limits. In many cases, the freedom of having your own NPDES and being in control of your own destiny is nice. However, the limits are much tighter. In many cases, most of our clients are probably pre-treating and then sending the wastewater over to the municipality. However, many of those municipalities have agreements that are at least as tight as the requirement if you had your own NPDES permit.

So I think that there are pluses and minuses to both. Typically, there are things like flow limits and constituent limits on all the wastewater either way. I’m not really sure that there’s a big difference in the whole outcome when you look at the big picture.

Jeff Walters (1:53)

But that’s something that we can help our clients with to make that determination if needed?

Darin Jacobs (1:58)

Absolutely. We are currently working with numerous clients, some of which are independent dischargers with their own NPDES permits. Others have a permit to discharge to municipalities. So we go both sides of that fence.

Jeff Walters (2:13)

Okay. All right. So what are some common environmental hurdles that you and your clients are working through these days?

Environmental Hurdles for Industrial Permitting

Darin Jacobs (2:20)

Probably the biggest ones right now in the wastewater side are in EPA Region 7 for example, which has new limits that are being promulgated like chloride, total phosphorus, and total nitrogen. Those are probably

the biggest ones that are the most difficult to deal with. However, many other clients are still a number of years, I won’t say behind, but a number of years backlogged and they’re actually getting tighter ammonia limits, which seems really simple and it generally can be dealt with pretty regular technologies. But many of the people who are getting ammonia limits will eventually get chloride and total phosphorus and total nitrogen. The total phosphorus and total nitrogen is a much larger investment typically and a much more complicated process for removal. And that applies whether you are discharging as a pre-treatment or as a final treatment kind of facility.

Jeff Walters (3:27)

Some of these constituents that are having tighter restrictions are we getting any kind of help from the state and federal agencies? Are they providing any kind of resource of value to us and our clients these days?

Financial Assistance

Darin Jacobs (3:43)

Typically, the industry gets no assistance financially or otherwise to meet limits. They are expected to do so. Municipal clients qualify for things like the SRF program in almost all the States around, the CDBG program occasionally in some fashion, sometimes economic development, it depends on the state you’re in, but basically there are some systems and programs in place to help municipalities. Industries typically do not qualify and do not get that kind of assistance.

Jeff Walters (4:16)

In terms of assistance, not financial assistance. Just good guidance from say, Iowa DNR and the Department of Natural Resources within our region as well as EPA. Are those agencies still holding up their end of the bargain in terms of the NPDES permitting or are they still an issue when it comes to getting these permits renewed, updated, new permits?

Darin Jacobs (4:42)

Well, there are two ways, I guess we would talk about that question. It really is not the responsibility of the state to assist in the manner of, hey, you ought to use this technology. Their role really is, you must meet this limit, and they are put in a position of you need to meet this numeric limit. How you do it is up to you, within the confines of regulations. So they certainly are not able to provide that kind of guidance. That’s why we are here to help industries and our clients.

Jeff Walters (5:17)

All right. So how do you think our Environmental Business Unit at Snyder can support your clients and our projects?

Snyder’s Role in Assisting Industrial Clients

Darin Jacobs (5:26)

Well, that’s a good question. We help a lot of different industries and we help in a lot of different ways. Many of them are faced with meeting tighter pre-treatment limits and being the treatment plant designers, we can analyze the system they have currently in place, and many times we can help them by improving the existing treatment system, adding aeration, adding a detention time, adding flow equalization, things like that are much less expensive than redesigning and rebuilding the entire system. In many cases, we often help them by rethinking upstream processes to reduce the waste streams. We were very successful in doing this in a couple of different industries. One, in particular, a food industry had a very large chloride flow and chlorides have become a big issue and their new NPDES permit required a significant reduction in chloride being discharged and we helped them by going through some of the upstream processes to reduce the chlorides being put in the water.

According to the EPA, there is no practical and cost-effective method for reducing chlorides once they’re in the water, but they’re relatively simple to keep out. In many cases, the largest contributor to chlorides is simply softening of water. Most people have water softeners in their homes, they put salt in them. The byproduct of recharging the water softener is chloride, and industry is no different. And for example, we were able to run upstream and work with them on things like that. We also help by developing nutrient reduction strategies to reduce total phosphorus and total nitrogen. In many cases, that is not concrete and steel. In many cases, it’s assistance trying to find alternative methods with which to do the work. Oftentimes total phosphorus, for example, comes from cleaning chemicals. Now there are limits because FDA and USDA have requirements for cleanliness in these plants, of course. However, if we can rethink some of the cleaning chemicals, reducing the phosphoric acid, for example, that is used, we can reduce total phosphorus in the discharge of the plant. It didn’t really cost much to do that versus building a lot of concrete and steel. And in many cases, we also help by providing or helping design new technology equipment to help them better meet their needs.

One of the things we do try to do is think outside of the box. I think sometimes that engineers get tied up in gee whiz, we have to find a concrete and steel kind of solution to everything. And that’s not always the case. I’ll give you an example of an unnamed industry that we got a call one day to help, and they had significant metals problems and metals of any kind create a lot of problems for meeting limits. And most of the processes do not take metals out of the wastewater very effectively. So I went down to the plant, and we looked, and we talked about it, and during the conversation, we were talking through their process, and I simply asked the question, is there something else we could do with this wash water that they were washing product with? Because that’s where they were picking up the metals, and all of a sudden, a bunch of their plant engineers looked at each other and said, well yeah, you know what we could do? And they went through a whole different thought process about let’s just eliminate the wash process, which in turn eliminated the need to spend a whole bunch of money trying to remove metals, which is not an easy process. And yes, we talked ourselves right out of a project there, I’m sure, but it was the right thing to do for our client. And you know what? They will remember that because we did the right and honest and correct thing for them.

Jeff Walters (9:33)

Yeah. I think what you’re saying is what we’ve been hearing from other people too, is just understanding our client’s needs. Getting to know them, getting to know their facilities is extremely important. And that’s one of the best ways we can support our clients. We don’t have to push solutions. We don’t have to push products. We can understand what they need to get through the day in and day out to meet their permit limits and run their facilities.

Darin Jacobs (10:02)

I think that’s right on. And you know, so many of these facilities are wholesalers to large companies that have very, very strong environmental stewardship requirements. I E. McDonald’s. McDonald’s has very stringent requirements for all of their suppliers, and they are serious, and all of their suppliers need to be serious, and they all know that, and they don’t need to be told by a regulator that the limit is here. They already want to do it because they need to do it.

Permitting for Industrial Projects

Jeff Walters (10:37)

How about on the actual permitting side? How can we best support our clients with the various permits that they may have, whether it’s NPDES permits, air quality permits, you name it, what are we doing to help those guys out with permitting?

Darin Jacobs (10:55)

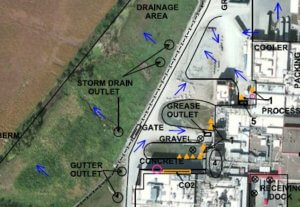

That’s a good question. We often help people with pre-treatment permits. We’re working on several, several companies right now who have pre-treatment permits to municipalities, and we’re able to analyze their current capabilities and work with the receiving municipality to adjust those permits in some cases or add technology to get better removal in some cases, in cases where our client has their own NPDES permit, we kind of go through the same process. They really have the possibility of all the things we just talked about, doing upstream improvements, doing concrete and steel improvements, and we can help them get to the point of being able to meet that NPDES permit. We also help with air permitting. Numerous clients need air permits for generators and for their process. And we can help with that. And one of the ones that sometimes sneaks up on people is stormwater permitting. To meet the requirements of stormwater permitting, a facility has to have a multifaceted approach. It’s not just the stormwater that runs off of a construction site, as you know. You know that there are other permits required if you have industrial equipment sitting outside in a so-called boneyard, there’s an industrial permit for that.

Jeff Walters (12:15)

There are far more stormwater permits through EPA and DNR these days. And there were just a few years ago, a long time ago, we had general permit number one, number two, and number three for various uses. But the general permit, number one for industrial discharge with stormwater, that’s a big one. And when the DNR comes down on those facilities that may not have a good stormwater discharge or an SWPPP for a facility that doesn’t have an industrial SWPPP and they’re discharging stormwater, and it could be intermingling with who knows what within the facility, that can be a big problem for those industries.

Darin Jacobs (12:57)

Oh, absolutely. You know, if you’re storing oil, if you’re storing hydraulic fluid, diesel fuel for your generators, anything like that, transformers for electrical components, all of that falls under that industrial stormwater pocket and can become a real problem.

Jeff Walters (13:15)

Yeah, very foreseeable for some of these larger facilities to have their industrial NPDES permit or stormwater permit, their NPDES permit. These facilities seem to be constantly, you know, building and growing, so they probably have some stormwater permits for construction activities. It really can take a small army of people to understand all these permits and keep these facilities going until they don’t get those notices of violations from the DNR.

Darin Jacobs (13:44)

Right. And, you know, part of what we help our clients with is becoming part of their staff. Most of these companies are really, really good at the product that they are making. Be it pet food, be it burgers, be it a cement powder. They’re really good at that. They often struggle with the environmental side because those people don’t do it every day. We do it every day and we’re pretty good at it and we can join their team and we can become part of their staff. And when we’re not needed, we simply walk away. If we’re needed, they can call us and we can help them out.

Jeff Walters (14:22)

Yeah. Puts us in a pretty good position. I think that’s great. So Darin, what do you think are some foreseeable changes that you anticipate for your client in the future?

Foreseeable Industry Trends

Darin Jacobs (14:33)

Well, I think that certainly effluent limits will get more and more stringent. I don’t care what state you’re in. That’s going to be the case. And of particular concern for a lot of folks is chloride because, as we talked earlier chloride, there really is no cost-effective way to remove it once it’s in the water. That’s a big one. The other ones are total phosphorus and total nitrogen, also which are becoming under extreme pressure because of the dead zone in the Gulf of Mexico. And so, the pressure has come all the way up the Mississippi and Missouri Rivers to reduce loads of phosphorous and nitrogen because it reduces algae blooms. And I think that pressure will continue to grow. If you haven’t seen it yet, just wait. I’m sure you will see the regulation. It’s just a matter of time.

The other piece of this is higher technology processes. Every time we tick these numbers down tighter and tighter, the process control and the technology required to get to the result often become much higher. The good thing, however, is we can oftentimes control these facilities and these processes with really high technology also, which allows the operators to go off and do things that humans need to do. Humans don’t need to open and close valves anymore. Computers can do that. Humans need to put their thought out on how to do things smarter and better. And we can do that. And I do believe that will continue.

Jeff Walters (16:07)

So what I’m hearing from you, just like I hear from other people, is that regulation isn’t going away, and it’s getting a lot tougher day in and day out, year in and year out. And we need to be careful and cognizant of the best available technology, so we don’t let things get spun out of control and have our industry and facilities spend way more money than they need to control their discharge and continue to use both technology and the human mind to balance each other out and allow a facility to run without issue.

Darin Jacobs (16:44)

I think that’s a fair statement. It’s not going to get easier.

Jeff Walters (16:49)

Yeah. I think that’s a very fair statement that no matter what facility or industry you’re in if you have state or federal guidelines pertaining to the environment every year, it just gets a little bit tougher and it’s up to us to really understand what’s coming, in front of us so that we understand the rules, the laws, and we can convey that information to our clients.