Preventative Sanitary Sewer System Maintenance Promotes Cost-Savings

Preventative maintenance ensures sanitary sewers remain in proper working condition and helps prevent potential problems. Recognizing the benefits of a proactive approach, the Des Moines Metropolitan Wastewater Reclamation Authority (WRA) initiated an evaluation of their trunk sanitary sewer system.

As part of a multi-tiered wastewater collection system, large trunk sewers convey waste to the wastewater treatment plant utilizing smaller tributaries. On this project, the inspected trunk system included sewers installed before 2004. The oldest segments dated back to pre-1960, so the potential for deficiencies was a concern.

Through the evaluation, the WRA and Snyder & Associates aimed to establish a baseline for the overall health of the trunk system and use it in creating a wastewater asset management plan.

GIS & MSI Technology Assist with Sanitary Sewer Inspection

Inspections were conducted in two phases over 18 months. During the first phase, approximately 800 sewer manholes were structurally inspected and assessed for inflow and infiltration (I/I). A Geographic Information System (GIS) network was created to record the results, providing a user-friendly database to locate assets, document maintenance, and reference system conditions. This included all manhole structure inspections with corresponding photographs.

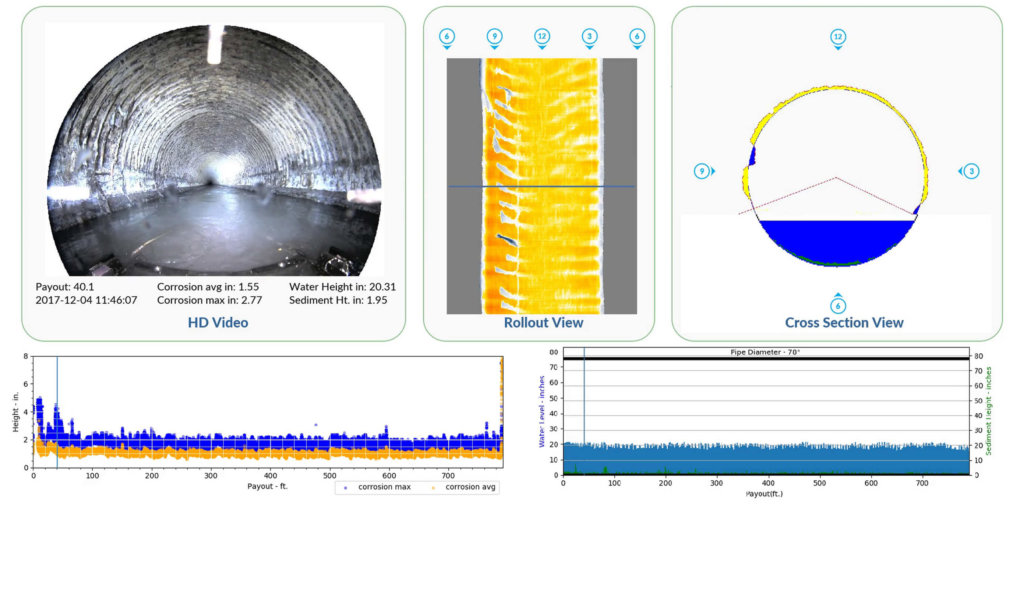

Multi-sensor inspection technology utilizes an HD camera, LiDAR, and sonar to create 360-degree pipe profiles during sewer system assessments.

The field investigation procedure began by assembling WRA mapping information for sewers and access structures, along with original construction and as-built drawings. Sewer manholes were surveyed utilizing GPS to obtain accurate locations. Most structures were determined to be in fair to good condition. Common issues included cracked or broken mortar seals and chimneys, offset frames, and broken or missing cover bolts.

During the second phase of inspections, nearly 60 miles of gravity sewer (15 inches to 96 inches), 13,000 feet of force main (12 inches to 24 inches), and 7,000 feet of siphon piping were evaluated using multi-sensor inspection (MSI) equipment.

For large diameter sanitary sewer trunks and interceptors, a visual-only inspection can be unreliable. With critical usage requirements, it’s not ideal to leave decision-makers with the tough task of evaluating which pipes might appear to be deteriorating. After a variety of inspection technology was considered, MSI was chosen for its ability to detect pipe corrosion severity during active flow.

MSI creates a 360-degree profile of pipes using a high-definition (HD) camera, LiDAR, and sonar equipment. The HD camera allows for a detailed visual inspection of each segment and records defects in a NASSCO Pipeline Assessment Certification Program (PACP) database. It also has a photo stitching process that allows the viewer to pan or rotate at any point during an inspection. The LiDAR information reveals corrosion characteristics to quantify the pipe wall loss of each segment, and sonar collects information from below the water line to tabulate debris volumes and estimate necessary cleaning needs. Digital reports and images from the MSI provide significant detail to assist in ranking the severity of defects.

Risk-Based Approach to Creating a Wastewater Asset Management Plan

Utilizing the data collected from the inspections, our wastewater engineering team utilized risk analysis methods to assess the health of the network and create an asset management plan for sewer rehabilitation. With costly rehab decisions at stake, risk management is a tool used to prioritize wastewater collection system resources for rehabilitation.

Sanitary sewer risk analysis is comprised of two factors—the likelihood of failure (LOF) and the consequence of failure (COF).

The LOF represents the sewer’s physical condition. The data collected data from the MSI was utilized to determine the likelihood of failure for each sewer segment. The likelihood of failure includes two components: overall pipe rating (OPR) and corrosion volume per inch diameter-feet. The (OPR) is a scoring system that ranks individual pipe segments by the visual defects that were recorded during the inspection. Overall pipe ratings by segment are placed in a matrix to calculate the likelihood of failure.

The COF considers the impact on the entire system and surrounding community if a specific segment were to fail. When wastewater utility assets fail without notice, the repair costs are typically exponentially higher when compared to planned rehabilitation. Similar to the likelihood of failure, a matrix system is used to assign weights and rate each segment.

By combining both factors (LOF and COF) into one (Risk), weak points in the system are identified with greater accuracy and more effectively prioritized for repair. This methodology ensures that dollars are spent cost-effectively and rehabilitation schedules are optimized. It also helps prevent environmental and human health implications.

To calculate risk, the LOF and COF ratings are multiplied together. Wastewater utility assets are prioritized based on the resulting risk rating. Risk scores are then sorted from high to low. Pipes associated with a higher risk score represent the primary candidates for rehabilitation. Once sorting is complete, a curve is generated and risk categories are defined which includes lowest, lower, moderate, higher, and highest risk.

Approximately 121 segments (or 20 percent) of the WRA’s sewer system were classified as high- to higher-risk assets. The areas that currently present the highest risk lie within the Southwest Outfall and South Side Interceptor located south of downtown and parallel to the Des Moines River. These sewers act as the lifeline of the metropolitan sewer system.

Wastewater Asset Management Plan for Sanitary Sewer System

As a result of the sewer system assessment, two phases of pipelining are recommended. Both phases of sewer lining will address several of the highest-risk segments while presenting the best opportunity to meet budget goals. The sewers in this area have particularly flat slopes that result in low velocities and create an ideal environment for corrosive conditions. Priority lining will prevent further deterioration of the sewer and ensure that assets are repaired before unexpected failures occur.

The design is currently underway for both phases by the Snyder & Associates’ team with lining anticipated to be completed in 2021. Snyder & Associates continues to assist the WRA in identifying other areas of priority and planning additional phases of rehabilitation for future programming.

Services provided by Snyder & Associates include construction administration, GIS and asset management, GIS mapping and analysis, along with wastewater system analysis and planning.