Crucial Role of Distribution Networks in Community Water Supply Services

With many communities nationwide experiencing steady or robust expansion, thousands of miles of new water distribution pipes are installed yearly. This is in addition to the hundreds of thousands of miles of existing water distribution pipes. Municipalities depend on these winding, interconnected networks to deliver consumers an uninterrupted supply of high-quality, pressurized, potable water. They also provide water for practices such as fire suppression and landscape irrigation.

Because distribution systems represent the physical bulk of the water supply infrastructure, they’re also the primary challenge from an operational and public health standpoint. When problems arise within a system, higher costs and inefficient service are often the result.

An in-depth water system study can generally identify distribution system deficiencies and any necessary infrastructure modifications. Using these studies as a foundation, the water experts at Snyder & Associates work closely with client communities to develop distribution system models and detailed designs that ultimately help the community maintain the quality and safety of their drinking water.

Essential Elements of a Water Distribution System

Beyond the water pipes, an entire distribution system consists of pumps, valves, storage facilities, and other hydraulic equipment that connects drinking water treatment plants to the consumer’s tap. Each of these components plays a critical role in efficient water transfer.

The pipes that carry water from the treatment plant (or the source in the absence of a treatment facility) to the consumer are often categorized from largest to smallest: transmission (or trunk), distribution, and service lines.

As water flows through the pipes, the pressure fluctuates depending on the surrounding topography and elevations. The higher the elevation, the more effort it takes to move the water, often necessitating the installation of a booster pumping station. The pumps add pressure to the system, pushing the water to a higher elevation, such as to the top of a hill or into a water storage tower.

Water distribution systems are constructed to provide sufficient water pressure to all customers. If left unchecked, however, the customers closest to the top of the hill would receive lower pressures, and those at the bottom would experience higher pressure. To maintain consistency, valves are used to control flows and pressure within the system. They’re also used to isolate sections for maintenance and repair.

Spacing for valves depends on the size and prioritization of a pipe. In urban distribution systems, valves are typically positioned about a block apart. This spacing is adequate to maintain the proper pressure and allows maintenance crews to isolate one segment at a time for repairs. In rural areas, valves can be farther apart due to a considerable distance between service lines.

Finally, most communities also need a water storage facility. Elevated tanks are the most frequently used, but in-ground tanks and open or closed reservoirs are also options. These tanks and reservoirs provide storage capacity to meet fluctuations in demand, reserve an adequate supply for firefighting and emergency needs, and stabilize pressures within the distribution system.

To successfully move water through a community, pipes must carry adequate amounts of water, pumps must create flow and provide pressure, valves must open and close properly, and storage structures must hold and maintain the water. All these elements must work together from beginning to end to create a fully functioning water distribution system. However, one more piece to this infrastructure puzzle is how all these distribution elements are configured.

Major Pipe Distribution Network Configurations

In many legacy distribution systems, pipes and other utilities are commonly buried underground. The design of these networks depends on the specific topography and the street layout in each community. When planning expansions or renovations, however, municipalities have multiple configuration options, but the two most commonly used design s are the grid/looped and branch systems.

s are the grid/looped and branch systems.

Grid/Looped Configuration

A grid or looped system consisting of connected pipe loops throughout the served area is the most widely used configuration in large municipalities. In this system, there are numerous pathways that water can follow from the source to the consumer. By keeping water moving, the looping pattern reduces innumerable issues associated with water stagnation and increases firefighting capacity. However, dead ends can still be created, especially in suburban areas with numerous cul-de-sacs. Water quality problems can arise, and frequent system flushing is required.

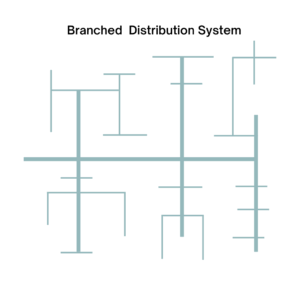

Branch Configuration

A branched system is similar in appearance to a tree, where smaller pipes divide off from larger trunks throughout the service area. This system is standard in older communities and cities without a definite pattern of roads. With pipes descending in size, a branch format restricts the water flow to follow only one pathway from the source to the consumer. Because of this limitation, the further down the line water travels, the lower the pressure. To mitigate this, sporadic pumping stations are required across the network to add pressure and get the water to the end of the line. Additionally, as the pressure in the system drops, the flow volume is reduced, causing limited firefighting ability.

To mitigate this, sporadic pumping stations are required across the network to add pressure and get the water to the end of the line. Additionally, as the pressure in the system drops, the flow volume is reduced, causing limited firefighting ability.

The components of every water distribution system are selected considering the pressure requirements, overall system length, potential growth areas, staff time commitment for operation and maintenance, and desired fire protection. Whether you’re in an expanding community or an older area needing renovations, our team of experts can examine your infrastructure needs to help you determine which system is appropriate for your community.

Common Water Distribution System Failures

Understanding the root cause of standard pipe and distribution network issues allows communities to correct minor problems before they become major concerns. Internal and external factors can affect overall flow efficiency and reduce water quality, violating set water quality regulations and standards and creating potential public health risks. Our experts most commonly encounter this listing of distribution system issues during condition assessments.

Stagnancy

In systems with minimal movement or aeration, stagnant water becomes a prime breeding ground for biofilms to begin coating pipes and storage facilities. Left unmanaged, bacteria will grow and flourish in these biofilms, creating ideal conditions for dangerous diseases and pathogens to grow. One sign of stagnancy is the loss of chlorine residuals and the inability to maintain sufficient levels.

Cross Connections

A cross connection is where non-potable water or contaminants may enter the treated water. This external contamination can enter a distribution system through submerged plumbing fixtures, creating water pressure at the pipe’s exit. Pressure moves water, and if the pressure of the contaminated water is greater than the potable water system, the water flow is temporarily reversed, allowing contamination to enter the system.

Corrosion

Noted as one of the most common problems affecting community water supplies, the chemical processes experienced during corrosion slowly dissolve metal, causing systems to deteriorate and fail. Signs of system corrosion include a pattern of water main breaks on metallic pipes such as cast iron and ductile iron (breaks are much less frequent on plastic pipes). Areas with brass, lead, copper pipes, or soldered connections at fixtures are particularly at risk of corrosion.

Water Main Breaks

As the backbone of a city’s interconnected water system, water main breaks can cause significant service outages and water contamination. Corroded pipes and quick changes in system pressure, extreme temperature changes, construction incidents, or age can cause these ruptures. During a water main break, strategically located valves are critical to isolate the break, prevent contamination within the pipe, and maintain service to areas outside of the break area. A lack of valves can cause a complete system shutdown and temporary boil orders until testing deems the water safe again.

Long-Term Water Supply Distribution Viability & Replacement Needs

The need for upgrades in the nation’s vast water supply systems has never been greater. In a 2018 inspection and subsequent report, the U.S. Environmental Protection Agency (EPA) found that drinking water infrastructure would require nearly $500 billion in maintenance and improvements over the next 20 years.

While substantial, this figure does not include the added cost of lead service line replacements for systems installed before 1988. As of August 2022, Lead and Copper Rule Revisions (LCRR) require water system operators to create and maintain an inventory of service line materials by October 2024. To manage the high cost of maintaining regulatory compliance, utilities must engage in regular and proactive infrastructure assessments, maintenance, and replacement programs to avoid frequent system failures and forced compliance issued by regulatory agencies.

Snyder & Associates’ Role in Distribution System Updates

Our seasoned water infrastructure team can assist communities in big projects, such as planning for significant expansion and growth of their water systems and systematic improvements, or help with smaller, individualized pipe assessments and repair recommendations.

When tackling these projects, our first step is creating a preliminary engineering report. Multiple research efforts are conducted to ensure this document clearly shows the needs of a community’s distribution system. These include reviewing maps of current systems, discussing known issues with city operators, and reviewing Department of Natural Resources (DNR) safety reports and monthly operating reports to see daily water usage, chemical feed rates, and levels of known contaminants. Additional testing is usually recommended to identify contaminants that are not being tested or treated to ensure a complete picture of the system.

Our experts then use the information collected in their engineering report to recommend options ranging from minor adjustments to major improvement projects. We will work side by side to identify and secure available funding options and ensure the necessary steps are taken to finalize a successful water distribution project that can serve your community for many generations.