Selecting Right-Sized Treatments for Small-Town Wastewater Systems

Identifying proper wastewater treatment solutions for small towns requires the acknowledgment that these communities function differently from large urban centers. As small towns across the country find it challenging to keep pace with the changing wastewater limits and regulations, our engineers are prepared to help.

Listen in as our engineer Jeff Godwin, P.E., details common wastewater concerns and issues associated with rural systems and explores the multiple treatment options specifically fitted for small-town wastewater treatment systems.

Webinar Agenda

- Common Wastewater Treatment Concerns (00:18)

- Primary Treatment Options for Small Towns (1:22)

- Determining the Correct Treatment Option for Your Community (3:17)

- Creating a Wastewater Facility Plan (3:58)

- Lagoon Improvement Options (8:37)

- Available Funding Options for Wastewater Treatment Systems (14:28)

- Getting Started on Wastewater Treatment System Updates (18:28)

Jeff Godwin, P.E.

Civil EngineerJeff Godwin, P.E.

Civil EngineerStormwater Management, Erosion Control, Wastewater Treatment Systems, and Water Supply Systems

Common Wastewater Treatment Concerns (00:18)

Hi, this is Jeff Godwin. I’m an engineer with Snyder & Associates in Atlantic, Iowa, and today I’d like to talk to you about small-town wastewater treatment options.

Many small towns are faced with wastewater treatment concerns, so we’re going to talk about that a little bit. We also have some different options available for how to treat those concerns, along with some common funding sources to help those towns find the funding they need for these projects.

Some of the most common wastewater treatment concerns might be high levels of inflow and infiltration, which can overload the existing wastewater treatment system. Another concern might be aging infrastructure, which causes higher operation and maintenance costs. A community sometimes outgrows the capacity of its current system, and other issues might be failing to meet the NPDES permit limits on the effluent, or if they get an NPDES permit renewal, it may include tighter limits for those effluent levels.

Primary Treatment Options for Small Towns (1:22)

Controlled Discharge Lagoon

So, going on to some of the most common treatment options that small towns can use to treat these issues. The simplest and most easy to manage would be a controlled discharge lagoon. Quite simply, that’s just a lagoon that holds six months’ worth of effluent at a time, and twice a year, you would discharge from that lagoon to the outlet, the outfall of your system.

Sand Filter

Another common method for smaller communities is a sand filter. You would send that wastewater through a sand filter, and it works a lot like a septic tank.

Continuous Discharge Lagoon

As you move up the ladder to a little bit more technology, you might have a continuous discharge lagoon where each day, you have water in and water out. Oftentimes these require mechanical aeration or possibly adding air with blowers. Some new technology that we’ve seen in the last 15 or 20 years include technology like a Leman system, which is a floating cover to keep the water warmer in the fall and spring. That would be supplemented with blowers for aeration, along with what they call a polishing reactor, which is just a slightly different configuration of air in a concrete tank after it leaves the lagoons. Another option would be a submerged attached growth reactor, commonly referred to as a SAGR system.

Those have very large gravel beds, which the wastewater travels through. The gravel gives those bacteria a surface to live on and can give some very good results for wastewater treatment.

Mechanical Treatment Plant

And then, at the top of the pile, mechanical treatment plants would be the most intensive, and from both a financial cost point of view and also a day-to-day operation point of view, they would be the most complicated and most expensive type of treatment.

Determining the Correct Treatment Option for Your Community (3:17)

As I get started, I just thought I’d remind you all that all wastewater treatment needs have some common elements, and one of those is time. How much time does your water have in your system before it moves on? How much space do you have? So, if you have more space, you can get more time, and that would require less added oxygen. In other words, nature can provide enough oxygen. That’s how the controlled discharge lagoon works. If you have smaller storage space, that means smaller time available to store that wastewater, and that means more oxygen is required through artificial treatments with blowers and pumps.

Creating a Wastewater Facility Plan (3:58)

So, as you start down this path, one of the first things that the Iowa DNR will require of you is to have an engineer help you write a facility plan. When we work on a facility plan for a community, we start with a statistical analysis of your current flows and loads. We submit that analysis to DNR, and we recommend some design values based on those flows and loads, and DNR concurs with those numbers. After that, we evaluate the best treatment options for loading of that size, and we submit a final report to DNR for consideration. After that, we can move on to the next steps.

Inflow & Infiltration Reduction & Control (4:43)

If you need inflow and infiltration control, one of the best ways to get that is to go out into your collection system in town and consider using a cured-in-place pipe lining to your sewer pipes. You can also grout each T service connection from a house or a business into your sewer main. If it’s not a manufactured PVCT, there’s generally some open soil around that tea connection. If you just break a hole in an existing sewer main and add a service by sticking a pipe into the hole, maybe dump a bag or a sat crate around it. Then that T often allows water into your system.

By grouting it, what we do allows that connection to be watertight. The sewer companies have these small robotic crawlers that can go through your pipes. They can televise them, they can see issues that we cannot see from above the ground, and they can also pump in and pressurize some chemical grout into that soil, which turns it into cement. We can also look at grouting your manholes either on the exterior in the soil, or if you have the old-style red brick manholes, we can do a spray-on grout concrete layer on the inside of those bricks to help prevent water from coming into those systems.

The final, most important way to reduce your inflow and infiltration is just adjusting your manhole castings at the street level. Making sure that the lids fit tightly, making sure that the casting is properly fastened to the manhole itself as well as proper sealing of those joint connections. Also, make sure that the lid of the manhole is not in a low spot. Don’t make that a spot where water collects, or it will find its way around that lid and down into your system.

Controlled Discharge Lagoon

Moving on, I’ve got some photos here.

Typical controlled discharge lagoon showing some shoreline protection. It’s very common for lagoons to have a rock edge to prevent shoreline erosion. A controlled discharge lagoon would be quite large in many cases simply because it needs to offer the proper storage for the full six months. They are a very simple operation. They don’t require any electricity. They require a few manholes and valves and site piping, and you also have both primary and secondary cells in those systems.

Sand Filter System

If you have a sand filter type system, this particular sand filter has the inflow in PVC pipes over the top of the sand. It sprinkles that inflow water into the sand. It filters down through four feet of sand to an exit pipe, and then it’s released. They recycle part of that water back through a second time to get a little better treatment. These operations are still fairly simple to manage. They have a small electrical requirement. They do have manholes and flow splitters, valves, and site piping involved. And often, they have an equalization base in our tank on the front side of the sand filter because it’s not a 24/7 pumping of water into the sand filter. In those cases, it’s more they pump five minutes each hour or something like that, and then they let the system work.

Continuous Discharge Lagoon

A continuous discharge lagoon. Quite often, it’s a little bit smaller than a controlled discharge lagoon. In this case, you can see a floating mechanical aerator that’s just a propeller on a shaft below an electric motor and mixes this oxygen into the water that way. They’re a simple operation. Medium-level doctoral requirement manholes, flow splitters, and valve site piping. You’re going to see those on all of these systems. They do require blowers and mechanical aerators to be sure that there’s enough oxygen in the system to properly lower the BOD and ammonia levels before letting this water out into the stream.

Lagoon Improvement Options (8:37)

SAGR Unit

Other lagoon improvement options are a little higher in technology. This happens to be a Sager unit, which is a four-cell Sager with a blower and a UV building shown. Each of these four cells is approximately 24 feet wide and 200 feet long. It’s hard to see it in the photo, but out in the center between the four cells are some splitter structures. And so, your info from your lagoon comes and splits 50-50 into the first two cells. Then after it leaves these two cells, it goes to a second splitter structure, and it splits 50-50 into the secondary cells, the third and fourth cells. The boiler building has blowers running 24 hours a day. Some of that air goes to aeration in the lagoons. Some of that air goes to the Sager cells themselves. And you can see these black pipes in the corners, that’s your air valves to send the air down to the pipes at the bottom of the sager cell.

This next photo shows during construction. The SAGER cell is lined with a membrane for water tightness. The arched PVC in the center of the cell is for the flow to exit after it’s gone through this treatment. You can see they’re using a notched two by six to keep the small pipes equally spaced as they put gravel over those. And they slide that along as they move the gravel forward. Then they will eventually fill the entire cell with gravel. Along the two outside edges, there will be some piping for the inflow of water into these systems.

Floating Cover

This is an example of a floating cover. This one happens to have mechanical aeration with the floating cover, but it’s much more common to have blowers with air piping underneath the floating covers. Both of those systems, they’re a medium level of complexity for the operator. They have more affluent testing requirements. They have higher electrical requirements. They do contain manholes, flow splits, valves, and site piping, and they will have blowers involved. And just for an example, this is one type of blower. Others are enclosed in a soundproof case, so they’re more of a cube look. But inside the cube is, is basically the same configuration. They have regular maintenance requirements of changing the oil and changing the belts after so many hours of use on a regular cycle. Also, then out in the lagoon are these diffusers that hang to the bottom of the lagoon from the air piping. Each of these fingers is a porous PVC material, which puts out millions of microscopic size bubbles into your lagoon water to promote oxygen and keep the levels high enough to properly treat the wastewater.

Lemna System

This is a polishing reactor, which is part of a Lemna system. You can see air piping along the top edge of the concrete wall. You can see the air piping heading down under the water to diffuser pipes. It’s got a floating cover on it, and there’s a cube of mesh PVC material hanging in there, which the purpose of that is just to give surface area for those bacteria to live on.

UV Disinfection

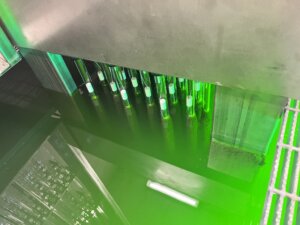

So, in many of these higher-level systems, UV disinfection is required by DNR. This is one example of what a UV building may look like. In this particular example, the water flows through a channel on the floor.

That channel is formed into the concrete, and then we hang the UV lights in that channel. You can see the control box for the UV lights above the floor, but the lights themselves are down underneath the grid, so we don’t see those in this photo. A smaller system may be just a stainless-steel channel that’s outdoors, and it just sits on a pad adjacent to your other treatment. Here you can see the banks of lights as they hang down into the wastewater stream. There’s a weir at the end of this to control the water level to keep the lights covered. Generally, they size the number of lights based on how long the flow time is through this channel.

So UV disinfection is a medium level of up complexity as well. It’s not too hard to operate. It does require some effluent testing as well as a pretty high electrical requirement for those lights. Higher monitoring requirements to make sure it’s operating properly each day. And then a maintenance cost of replacing the bulbs on our regular schedule. The good news is you don’t need to run these through the winter months, so you can just pull the bulbs and leave them inactive, depending on your permit through the winter months.

As I mentioned earlier, a mechanical plant would be the most complex wastewater treatment, but once you get to a little bit larger town, perhaps a town, with a little bit of industrial loading, these are very efficient at what they do. It’s just a little bit more complex way of dealing with it. And so, this is just a sample drawing. What you’re seeing is the outline of concrete tanks, and they’re fairly small, so the volume of storage might only be a couple of days of flow. It requires quite a few pumps and quite a few blowers to keep the water oxygen high enough as well as keep that water moving through the stages of treatment. And then there would also be UV treatment at the end of a mechanical plant.

This is probably the highest level of operation we would ever see in small-town Iowa. There are more affluent testing requirements and higher electrical requirements. Still contains the manhole flow, splitters valves, and site piping that we need to get our water from place to place. As well as quite a few blowers and pumps.

Available Funding Options for Wastewater Treatment Systems (14:28)

How does a small town afford these expensive systems? You don’t have a large number of customers. You don’t have a high base to pay for a multimillion-dollar project. The Iowa Economic Development Authority offers community development block grants, and this is income based, so greater than 50% of the households in your community need to be low to moderate income to qualify for these grants. They have a standard list of communities that are eligible based on census data. But if your community is close to the limit, you are allowed to do an income survey and submit those results to show eligibility if you are not on the list. The applications for this are due quarterly, at the end of March, the end of June, the end of September, end of December. This money, if you get this grant, will require Davis-Bacon wages for the project, and one of the local councils of government around the state will help you administer these funds.

CDBG Grant

The grant amount of a CDBG loan is based on population, and so if you are a:

- Town of fewer than 300 people, you can get up to $1,000 per person.

- If you are 300 to a thousand population, the maximum grant is $300,000.

- If you are 1,001 to 2,500 people, the maximum grant is $500,000.

- 2,501 to 15,000 population, the maximum grant is $600,000.

- Greater than 15,000 population, the maximum grant is $800,000.

These are the maximum limits, but the grant is also limited to approximately 45% of the total project cost.

SRF Funding

State revolving fund offers 20-year loans through the clean water program. There’s there is a step-by-step process that you go through with an engineer from the facility plans through design and construction. It does require Davis-Bacon wages. There are planning and design loans available to just pay engineering fees for activities done before construction. And those loans are at 0% interest until they are combined with the construction loan at the end of the project. Then, of course, they have an interest at that time. The construction loan offered through the SRF program is at one and three-quarters percent interest with a quarter percent maintenance fee, half percent origination fee, and a 20-year term.

USDA Rural Development

There’s also some funding available through USDA Rural Development. They have offices in several places around the state. That is a continuous application period. If you are interested in trying to work with them, you just simply need to contact them and get one of their representatives to meet with you. Often, they will include the engineer in these conversations, and they will talk about your project and talk about how it could fit their programs. They offer three levels of funding, and the rates are adjusted quarterly. Currently, the low-income community is available for a 2% loan for up to 40 years. If they determine that your income level is in the intermediate level, then it’s two and five-eighths percent. If it’s a market rate community, which is above average income, then it’s three and three eighths’ percent for those loans.

And so you can see the communities with a little bit higher incomes, this is a less attractive program simply because these rates are quite a bit higher than SRF at this time. Now, grants may be offered as part of this financing offer, and most commonly, those grants go to low-income communities with a maximum grant of 75%. We have seen some small communities with a population of around a hundred nearly get the full 75% grant, while in communities with maybe three to 700 people, it’s more common for them to get a grant in the 50% range or less.

Getting Started on Wastewater Treatment System Updates (18:28)

So, in summary, just know that if you have concerns with your wastewater treatment system, you are not alone. Reach out to your neighboring cities, talk to other operators in your area, and reach out to your IDNR field staff. They are there to help you, and oftentimes they have some suggestions to help operate your system more efficiently, as well as consulting engineers. We are here to help you decide how serious your problem is and then also to help walk you through the steps to get something in place to treat the water better than it had been. There are lots of options out there. There’s lots of new technology. Just be sure to get some good advice about the best options for your system and your community.

For funding, there is lots of funding available. Just get some good financial advice from your financial planner about which option is best for you. So, thank you for your time today. I look forward to working with you, and if you need anything, feel free to reach out to us, and we’ll do our best to give you some advice. Thank you.