Discernible Infrastructure Issues Lead to Inspection

The City of Council Bluffs was prompted to conduct video inspections of its sewer system after areas along Kenmore Avenue and Harrison Street began to sag and sewage smells wafted up from the floor drains of nearby residences. As city maintenance crews scoped the sewers, they found two areas that required immediate rehabilitation. Due to the extensive amount of work necessary for the project, a request for proposal was sent out and ultimately awarded to the team at Snyder & Associates.

Full Investigation of Community Piping Systems

Our partners with TREKK Design Group assessed all the defective pipes using a surveillance monitoring system.

At the outset, a full investigation of the extent of needed repairs was conducted. Using a surveillance monitoring system, our partners with TREKK Design Group provided a better visual of the affected pipes, allowing our team to assess the damage and structural integrity of the system thoroughly. This analysis showed that the aged pipes had experienced extensive wear and corrosion due to high groundwater levels and abnormal pavement/subgrade movement.

Initially, our team hoped to utilize a minimally intrusive lining process to repair all the defective pipes and avoid disrupting the street. However, sections of pipe had completely failed, ruling that option out in many areas. With a clear understanding of the damage, our engineers worked with city leaders to provide several different replacement and repair options that would provide the best solution within the allocated budget.

Kenmore Avenue Residential Sanitary Sewer Replacement

Approximately 1,000 linear feet of pipe were evaluated along the Kenmore Avenue location. Five different segments of pipe were identified where lining would be appropriate to seal off the areas damaged by corrosion. However, it was apparent that not all sections could use this method. Farther down the pipe, our team discovered a single segment stretching nearly 220 feet that was damaged beyond rehabilitation and required full reconstruction of the pipe and the connecting manholes.

The “remove and replace” process for this single section of pipe required the most invasive action and was scheduled for construction first. The area requiring replacement was marked off, and the portion of the street was cut open to reveal the damaged pipe. Once wastewater flows were redirected through a bypass system to a downstream sewer, the old pipe was removed, and its replacement was installed along with the two new manholes at either end of the section.

Due to the winding alignment of the roadway, hilly landscape, narrow right-of-way, and a sewer depth of approximately ten feet, this replacement process proved to be slightly more complicated than usual. Preserving the existing pavement was deemed futile, and a full-width street reconstruction was completed along this section. Additionally, with such a small work area, there was the potential for disruptions to adjacent yards, which could create erosion concerns due to the extreme land grades. As a preventative and proactive measure, our team set up inlet protection devices at existing storm drains and used silt fences along the yards and slopes to limit the amount of sediment transport.

CIPP Lining Reduces Costs & Disruptions

The remaining five segments of sanitary sewer pipe along Kenmore Avenue utilized Cured-In-Place-Pipe (CIPP) Lining. This rehabilitative technology uses a high-strength woven fiber tube coated with resin and pushed through the pipe. After insertion, the resin is cured using hot water or steam. This method helps protect and strengthen the pipe when completed, significantly extending its lifespan.

The manholes along the CIPP sections received centrifugally cast cementitious mortar lining with an epoxy coating. Both processes provide a structural and cost-effective solution to deteriorated and failing pipes and manholes. They require no digging or disruptions to existing pavement and only minor traffic disruptions to allow the equipment to sit over the top of the manholes.

Along with the overarching sewer rehabilitation, a small amount of associated storm sewer replacement and pavement repairs were needed along this stretch of Kenmore Avenue. As a full-service firm, we have both stormwater and pavement experts in-house who were able to lend their expertise to ensure these minimal issues were quickly resolved without the need for an outside consultant.

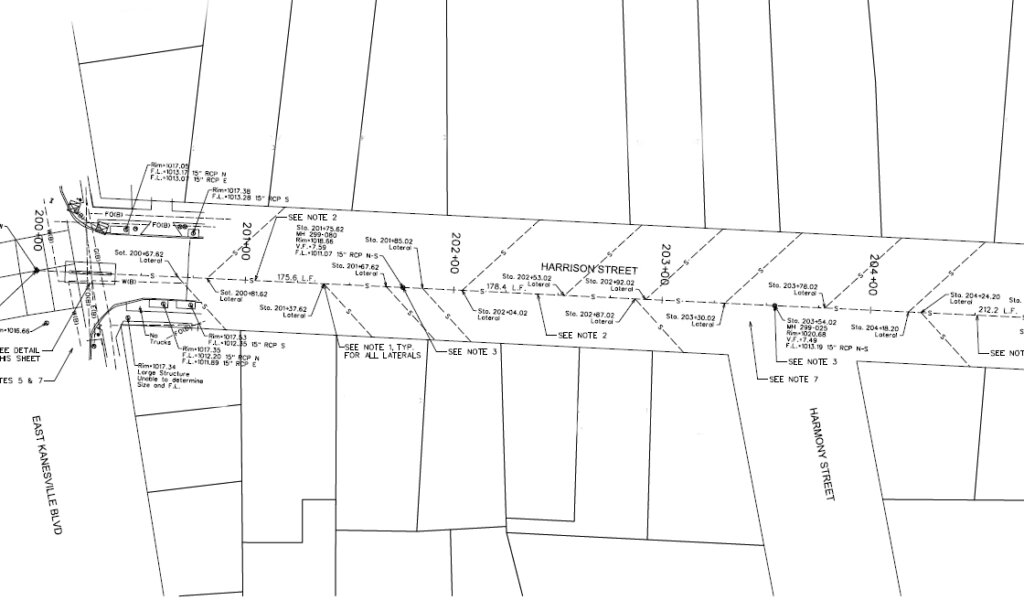

Harrison Street Sanitary Pipe Rehabilitation

Across town, the other area of concern was at the intersection of two major thoroughfares. The Harrison Street location had approximately 1,300 linear feet of pipe scoped and evaluated. After inspections, it was determined that a segment of 15″-diameter pipe stretching nearly 20 feet long would require a spot repair of removal and replacement. Because this sewer was only 7-8 feet deep, we could keep the limits of needed pavement removal to a trench width. The remaining 1280 linear feet of this location used the same CIPP Lining process as Kenmore Avenue, and the manholes received the centrifugally cast cementitious mortar lining with an epoxy coating.

Phased Construction & Strategic Public Engagement Limits Disruptions

Since Kenmore Avenue is primarily a residential roadway and Harrison Street is a central corridor through town, construction staging, and public engagement were high priorities during our design and planning process. To minimize disruptions to the residents of Kenmore Avenue, our team created informational door hangers detailing the project’s scope, the benefits residents would experience, and the estimated construction timeline. Although the road had to be closed during repairs, residents were kept informed and consistently updated.

At Snyder & Associates, we realize any disruption can impact daily life, and we strive to make the construction process as seamless as possible for all parties involved. With those sentiments in mind, our team was also able to keep Harrison Street’s total road closure time to one week by utilizing phased construction, minimally invasive processes, and quick-curing concrete.

Routine Inspections Can Prevent Costly Sewer Repairs

As civil engineers, our teams always stress the importance of routine sewer inspections and evaluations to prolong the life of existing pipes and avoid costly repairs. Inspections also help locate potential blockages in addition to major structural defects.

Heading into this project, our experts knew that each portion of this rehabilitation effort might require a different solution to best fit the condition and specific project location. Through clear, consistent communication and thoughtful planning, our team was able to find applicable resolutions to these complex sewer infrastructure issues without significant disruption to residents.