Aiding Industrial Clients with Design & Compliance

Industrial engineering is a vast field that encompasses a wide range of disciplines and activities. It involves analyzing complex production and operations to optimize output and minimize client costs. As the business world continues to become more complex, industrial engineering is becoming an invaluable asset for all kinds of organizations.

The central idea behind industrial engineering is to efficiently distribute resources such as labor, materials, energy, and capital. In our most recent podcast, our experts from diverse industrial backgrounds delve into the basics of industrial engineering and its many applications. They discuss how industrial engineering principles can be utilized to enhance output, streamline operations, and lower expenses.

Podcast Agenda

- Improving Industrial Processes (00:18)

- Common Industrial Challenges Our Clients Face (01:41)

- Industrial Trends Across the Midwest (04:42)

- Commonalities Across Industrial Clients (07:02)

- Aiding in Day-to-Day Design Operations (11:21)

- Providing Accurate Virtual Models (17:49)

- Best Available Technologies for Infrastructure Growth (19:23)

- Future Concerns with the Rise in New Technologies (27:11)

- Providing Results for Site Upgrades and Reconstruction of Existing Facilities (31:07)

Darin Jacobs, P.E.

Water Resources Work Group LeaderDarin Jacobs, P.E.

Water Resources Work Group LeaderMunicipal Water & Wastewater Planning, Water Quality Modeling, Railroad Design & Construction

Craig German, P.E.

Structural EngineerCraig German, P.E.

Structural EngineerManages projects for both public and private clients, new construction, rehabilitation, and demolition of existing structures.

Shawn Duke, P.E.

Civil EngineerShawn Duke, P.E.

Civil EngineerProject Management, Planning, Roadway design, Utility design, Site design, & Construction Administration

Jeff Walters, PWS

Environmental Sciences Work Group LeaderJeff Walters, PWS

Environmental Sciences Work Group LeaderWetland & Stream Delineation & Mitigation, 404 Permitting, Natural Resources Surveys, Lake & Stream Restoration

Improving Industrial Processes

Jeff Walters (00:18):

Hello, my name’s Jeff Walters with Snyder & Associates. Today we are going to talk about industrial clients and their industrial processes. I have with me Darin Jacobs, Shawn Duke, and Craig German. Can each of you give me a little bio about yourselves?

Darin Jacobs (00:36):

I’m Darin Jacobs. I am the Water Resources group leader at Snyder, concentrating primarily on water and wastewater for the past couple of decades. We handle wastewater, we handle water, we handle stormwater, we handle title five air permitting, and we handle rail transportation, so we get a wide variety of experience, particularly for the industry.

Shawn Duke (01:02):

Hello, I’m Shawn Duke. I’ve been a licensed engineer doing land development work for about 20 years now. Focused primarily on industrial, commercial, and residential development. But I’ve done quite a bit of industrial design and site development projects.

Craig German (01:18):

I’m Craig German. I’ve been doing structural engineering for over two decades now. Industrial clients have always been an important part of our client base. We get into the energy sectors, the fabrication sectors, and just about any industry in between.

Common Industrial Challenges Our Clients Face

Jeff Walters (01:41):

So, we’re going to talk about the industrial sector and the clients that represent our Snyder portfolio. Those are energy clients, industrial users, clients that produced wastewater, produced general waste that may need some sort of permit. These could be 24-hour days, seven-days a-week operations. They could be 12-hour shift work. There are a lot of different entities that represent the industrial sector, and we do a lot of work with them.

So starting with, what are some hot topics within the industrial sector that you guys are facing right now?

Wastewater Nutrients

Darin Jacobs (02:19):

Well, I would say one of the hot topics at the moment is certainly wastewater, and in particular, in wastewater is nutrients. Under the EPAs new guidance, almost all the states have been asked to reduce the nutrient flowing into the rivers and to the Gulf of Mexico. Nutrients amount to total nitrogen and total phosphorus.

Up until now, most treatment plants don’t do a stellar job at removing total P and total N. And we are oftentimes a very large contributor if we have a pre-treatment system, and I say we, the industry, or if the industry is running their treatment system, we have a significant amount of total N and total P to be treated at that system. That is certainly gaining more and more traction and more and more pressure from many states.

Supply Chain Factors

Shawn Duke (03:17):

One of the hot topics I’m dealing with lately has been more of the supply chain and how you factor that into site selection. I have a lot of different clients who, as they select a new manufacturer location, it’s not just about where they’re at in the country, but how can they also incorporate their suppliers so they can maybe be located in the same location, their same business park, even to the point where they can help ensure that they’re the ones that receive the parts or the raw ingredients they need to help build their items they’re manufacturing. I see a lot of that discussion as well as the trucking industry: how can we provide more parking, provide more storage, provide more warehousing as we have more and more of that shipping going on?

Craig German (04:01):

Yeah, I would second that, Shawn. We’ve been seeing kind of an uptick where our economy used to be on demand and just in time, and we’re seeing more surplus and stocking for the “what ifs” than we had in the past. So for decades, we were kind of transitioning, so they’ve got empty shelves of product and stuff, and they’re getting both the raw materials in just in time to turn those into products and then ship them back out without any storage on either end. Now we’re seeing a shift back to storage on both sides so that they have a product to maintain their process. So that’s a shift kind of back to where we were a decade or so ago.

Industrial Trends Across the Midwest

Jeff Walters (04:42):

Okay. Another hot topic that seems to be of importance right now is just land costs within the Midwest versus the coast or other bustling metropolitan areas outside of the Midwest. Are you guys noticing any kind of trends or pressures within your industrial clients to move their facilities into the Midwest? And if so, how are you combating that or making it easier for them to get here?

Shawn Duke (05:09):

I’ve noticed that we have a lot more interest in different manufacturers and different industrial entities that are looking to move their new factory at new warehousing to the Midwest because the land cost is cheaper than on the coast. Also, the other half of that is labor cost is lower in the Midwest as well. So they see a benefit to that as far as investing in the Midwest.

We have several different communities we’ve worked with that have growing industrial parks and business parks that are marketing towards that and helping to build that infrastructure before they have the industrial user identified. So they have a lot of ready-to-build sites coming online already where it’s a quicker process for someone to come in and identify the site and be ready to move right into the construction of their facility.

Jeff Walters (05:56):

Sure, and that’s something that we’ve done company-wide with the site certification process that’s been going on now for, well, probably the better part of a decade. Just like you said, Shawn, we are looking at certain sites and getting them shovel-ready with permitting survey infrastructure needs so that if a major industry wants to come into town, it’s shovel-ready and ready to go. That’s a good point.

Darin Jacobs (06:20):

I’ll even add a third thought to this part of it. And with all the rail design that we do, one of the things that the Midwest seems to be pretty good at is supplying rail service from multiple companies, several class two railroads, which would be the ones that are slightly smaller than the Union Pacific and the class ones of that size. They’re readily able and willing to serve these industries, and you couple that with the lower land and lower labor cost and good transportation on the highway sector, and you have a pretty good opportunity to build a facility somewhere in the Midwest.

Commonalities Across Industrial Clients

Jeff Walters (07:02):

Great. So thinking about your industrial clients, are there common threads or themes amongst your clients that we can touch upon so that we can kind of understand and integrate those issues into one specific area or one specific topic?

Shawn Duke (07:19):

I guess with a lot of the industrial clients I’ve worked with, a common thread has to do with kind of the facility layout. If you’re manufacturing, there’s a focus on where raw materials come in. How does the finished product come out? So how is your site layout, and how do you configure it? We’re spending more time thinking about where the trucks come in, how do they have a separate dock set up where they can unload and the material can come in, and that the inside process facility is designed more to flow through the entire building. Then on the other end, there’s an outflow, and that loads onto a different set of docks that will allow for quicker and less movement of materials inside and just a quicker process to exit the building and provide some more traffic flow throughout the site. So you aren’t fighting any incoming materials with the outgoing materials.

Jeff Walters (08:08):

So Shawn, along those lines, are there any particular engineering design tasks that you’re completing on a routine basis with these industrial clients?

Shawn Duke (08:18):

Yeah, I spend a lot of time focused on truck movements. So we’re doing some truck turning movements, trying to figure out how best to allow that maneuvering of trucks entering the building and then also be able to back into the docks without having conflicts in the movements. So you can have multiple trucks entering at the same time or backing into the docks at the same time and not conflicting with each other. We spend a lot of time focused on the site layout part of how the storage of the trailers function with the trucks coming in.

Some of the sites have a lot of empty trailers that they’ll come in, load the docks, then get left there and then moved by a pub truck or something else that just moves them out of the way, and then they store it on one side. But these are all raw materials that somebody will pick up eventually, or the trailers will be reused on the outgoing side. So we do spend a little time on the layout part of that as far as figuring out how best to store the materials and how best to allow for the truck maneuvering throughout this site.

Jeff Walters (09:12):

Okay. So within those facilities, you’re focusing on the internal transportation logistics of moving in and moving out the materials, as you said?

Shawn Duke (09:24):

Yeah, definitely.

Jeff Walters (09:26):

Okay, great.

Darin Jacobs (09:28):

I’d like to add to that as well. One project, in particular, we’re working on in addition to the truck side, we’re also doing the rail side. The whole idea of this project is to be able to bring things in by rail, transfer them to the truck, or vice versa. And this is a cold storage facility as well as a none tempered storage facility. And it’s exactly what Shawn says, we’ve got truck movement, we’ve got the rail, and we’ve got rail design and rail movement to coordinate together so that this facility is a cross-dock kind of situation.

Craig German (10:04):

And then we’re seeing more and more emphasis on at least evaluating in the concept phase: automation. So significant racking automation processes, both with the slab suspended from the structure, those kinds of things. A lot of that is discussed and thought out early on in the concept so that the structure can be laid out, sized, and set up to receive at the first opening or potentially into the future.

Jeff Walters (10:36):

So Craig, without going into too many corporate secrets, can you provide an example or two or maybe a little bit more depth in the process of what you are doing on the structural side of things?

Craig German (10:50):

So the challenge structurally is to get the right size elements in the right locations instead of just oversizing anything and everything. The effort really is intense earlier on to coordinate that and still capture some efficiencies, so you’re not paying for a lot of extra structure but putting it in the appropriate spot strategically.

Aiding in Day-to-Day Design Operations

Jeff Walters (11:21):

Okay. So thinking about your clients, what are some tasks that we’re doing to help them with their day-to-day operations? We’ve touched upon some design and permitting and concepts, but when we think about how our clients are operating in their facilities, and a lot of them are running 24/7, 365.

Are we working alongside them in some of these cases, and if so, what are some of those tasks?

Darin Jacobs (11:53):

Well, I would say we are working alongside them daily, and sometimes in the middle of the night, we have clients that run, of course, 24 hours a day, like you said, seven days a week. Particularly in food production, they run round the clock with only a few hours of downtime, where they perform system-wide cleaning. And the wastewater system, whether it’s a pre-treatment facility or a primary treatment facility, has to run continuously and has to deal with extremely high flows during cleanup and oftentimes low flows during the rest of the day. So, we design the system to be able to tolerate that and, in many cases, I have gotten phone calls in the middle of the night with questions, and we try to answer them if we can help

Jeff Walters (12:45):

And expand on that just a little bit more. Say your industrial client gives you a call in the morning and says, “Hey, I need you to get out to the facility in a couple of hours.” What are some things you might be doing, observing, watching, or taking note of if they have a particular issue? Maybe expand on a couple of examples of where you’ve gone to facilities and spent a day or two or week there helping them through some problems?

Primary Treatment Repairs

Darin Jacobs (13:14):

Yeah, fair enough. For example, at a particular facility, they run their primary treatment wastewater plant, and the activated sludge plant had developed a significant settling issue. Settling is a very important part of the process for wastewater. After it’s been aerated and is essentially done with the treatment process, we have to settle it so that we have clear water. They were having trouble. We drove out there, and we watched, and we helped, and we offered a review of what was going on and got other people on the phone so that we could start adding the chemicals necessary to improve, settling, and improve the overall process. And that happened in a matter of a few hours. It’s critical to do that. That’s just one of many that we do that kind of work with.

Jeff Walters (14:09):

Okay. Shawn or Craig, do you have any examples where you’re heading out to one of your industrial client sites, like I asked Darin, working with them for a day or two or week and getting neck deep in their operations to help them solve a problem?

Multi-Facet System Accessibility & Functionality

Shawn Duke (14:26):

What comes to mind for me, especially even on additions and different modifications to existing facilities, is we spend a lot of time discussing employee parking and kind of working through how you do shift chains, how do you do the switchover where you have maybe double the amount of parking but you don’t have all the space? Do we have stage timings? Do we focus on how to have enough parking but also not overload with land costs to add more parking as needed? If we can take some different shifts throughout the facility and separate their start and stop times a little bit to allow for waves of shifts to come in, spend a little bit of time doing that.

The other thing that comes to mind when we’ve done additions is how do we keep operations functioning and how can we design the new facility around their operations, so we have either a quick shutdown or a small shutdown to make a connection or how do we build onto a building without impacting their operations? Because they can’t experience an extended shutdown for a new facility. They need to keep functioning, keep operational during the whole entire edition construction.

Craig German (15:36):

On ours, we’ve been doing it for years where we’ll have a part of a piece of a project where we’ll come in, understand their operation, and keep them moving when they need a new piece of equipment or a new addition. The biggest piece of that gets to be the how and the when and the sequencing of that.

Lately, there’s been a little bit more of a need from our clients. It appears to be a little bit bigger part of that management, be a bigger leader in their meetings, getting the right people to the table at the right time and helping them see it from beginning to end and at least get that set up for success. Sometimes we continue along and manage that process throughout. Sometimes once we set the plan in motion, they’re able to take it from there, but their internal staff a lot of times are really good at their process and what they need to do to keep their product going in and out of the plant or their operation, and they need us to come in and work alongside them as seamlessly as possible and do that piece of it.

Virtual Modeling

Craig German (16:38):

The other piece we are starting to see more and more that some clients are starting to see some financial benefit too is parts or pieces of a virtual model of their existing operation. A lot of times, it’s not a whole-scale virtual model but parts and pieces. Some other entities certainly have full virtual models of that. It really just depends on where they can find the bottom line impact as it to be positive or negative with them. And these aren’t just brand new facilities, but also existing facilities with the scanning equipment and those technologies that are available now that help them forecast and plan financially and schedule-wise when things will need to be replaced. And then also, that virtual model of their facility assists in that coordination to a finer degree during the conception phase of it. So, we’re seeing an uptick in that to where the technologies of advanced to a point where that’s starting to improve their bottom line instead of being in addition to or add some cost to it. The cost-benefit to that is starting to improve as that technology advances.

Providing Accurate Virtual Models

Jeff Walters (17:49):

Okay, what are some of the steps that we take to help them with their virtual modeling, and what is Snyder doing task-wise for virtual modeling for these types of clients?

Craig German (18:01):

The very first piece is to have an understanding with them of what is available and how it will benefit them, and a lot of those decisions come into maintaining that system as well. One of the challenges still with the technology is the level of sophistication of it and the constant upgrading of it. So, for example, if clients need to hire a consultant to maintain their virtual model of the reality in real-time, that’s sometimes where the cost-benefit starts to drop off. So that is an important part of that conversation upfront. The other piece is what do they have for staff and internal capabilities and understanding. So the software, as they advance, gets more sophisticated, they also get more costly. So some pieces in the past that had been a gap was fully understanding what that would mean. We go in early on in those situations and talk to them not only from the initial implementation of it and those benefits but also about what maintaining that would mean specifically so that they can make a more educated decision, which ultimately then comes down to the cost-benefit for them.

Best Available Technologies for Infrastructure Growth

Jeff Walters (19:23):

That’s pretty cool. I didn’t even think about some of the things that we do. We could probably spend a-whole-other podcast on virtual modeling and how that impacts our clients, whether it’s industrial transportation or anything else. That’s pretty cool.

Moving on, Craig, you touched on technology. What are some of the best available technologies that we’re helping our clients with through the lens of permitting, through the lens of growth and development of their facilities?

Craig German (19:53):

From the structural infrastructure perspective of, it is those accurate electronic drawings, whether that’s 2D, 3D, or up to 7D, and the accurate part of that is the most important. We do get involved in projects where scans have been done not related to the real-world coordinates, but the biggest benefit we are providing to our clients is to locate those things accurately. And there are many software that are involved in that, but that is probably the bottom line most valuable item to them.

Jeff Walters (20:30):

Can you go into more detail and explain 7D?

Structural Cutting-Edge Technology: 7D Electronic Drawing

Craig German (20:35):

The 3D portion is the X, Y, and Z in space, and then the 4D is time. And when you start adding that into their model and their operation, that’s another level of value to it. 5, 6, and 7D, depending on whom you’re talking to on that, do change a little bit. But those last three pieces get into the forecasting part of the equation and the lifespan of things.

For example, if it’s an electric motor, you can have the RPMs, the horsepower, the weight, the geometry of that thing, the make of the model, and all that can be on that information within that model. So the 5, 6, and 7D portion of that is okay, now that it’s in place and we start the clock of usage, what will it be in the future, and when will it need to be replaced? So, if it’s got, for example, a 10-year lifespan, then you can start to forecast two-year financial demands for that facility, an operation to start to budget that in 10 years you’re going to need enough money to replace this thing. You can also track whether it’s getting maintained, if it’s a piece of equipment that requires greasing or oiling, you can even maintain maintenance records within that and keep all of that in that same system.

So those are some of the things that the 5, 6, and 7D incorporate is kind of the futuristic piece of that, and it can be powerful. The balance usually with our clients gets to be how much is too much, meaning their facility is already there, it’s real, they utilize it, and it does its thing. So the point with the virtual piece of it is keeping that virtual piece right-sized so that it is not a second plant or operation to maintain, but really an additional tool to help maintain the real one. The virtual one doesn’t make any income for them. It is a cost to them. The usage of that needs to remain appropriate so that that virtual piece is a cost/benefit and not a cost liability to their facility.

Jeff Walters (22:53):

That makes sense. That’s quite a detailed explanation. Thanks, Craig. Shawn, you had a couple of words of wisdom regarding the best available technology.

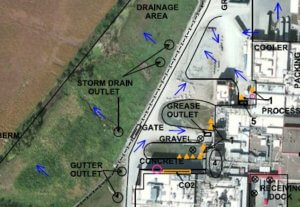

Stormwater Collections

A finalized SWPPP Map contains mark-ups specifying potential pollution outlets across the industrial facility.

Shawn Duke (23:01):

Yeah, one of the things we’ve started seeing is the more cutting-edge technology used for stormwater quality. We have a couple of different sites. One I can think of offhand here is they store a lot of metal materials outside and have also some trucks they produce, and their issues where they meet DNR permitting, they’re constantly having to provide some additional items to either catch metals before they get into the stormwater runoff or to catch hydrocarbons before they flow into the stream system. So that’s part of their NPDES permitting they have to constantly test the stormwater runoff in order to keep hitting their goals of runoff or different types of particles. They’re constantly looking for new and inventive ways to add to their existing system. One we came across was we started doing curb inlet inserts with some carbon pouches in them to help try to capture some of that stormwater runoff. It creates an extra maintenance item for them, but it was helping them achieve their goals to help eliminate some of their excess releases into the stormwater.

Jeff Walters (24:01):

Thanks, Shawn. How about you, Darin? In your world with industrial clients, what do you get going on for the best available technologies?

Wastewater Pre-Treatment

Darin Jacobs (24:09):

Well, I think I would speak from the wastewater treatment standpoint, and several of our clients, we’ve either helped them with pre-treatment using high technologies such as DAF, which is dissolved air flotation units that work very well, particularly in food production because it will recover greases fats and things like that that are normally in the wastewater and that cause problems with down street treatment and pumping processes. Most industries tend to have a pre-treatment agreement with the municipality in which they’re located. Not everyone, many of them, also have their own treatment facilities. In that case, if they have their own facility, oftentimes, we end up with an activated sludge treatment facility because they are so effective at treating almost everything, and they’re very effective at getting the first few steps done for nutrient reduction, as we talked about earlier.

The other issue that we’re running into more and more with industry is chloride. That seems strange, but the EPA has really been pressing hard on the reduction of chlorides going into waterways. Part of that comes from the fact that just about every time water is used, and that is, it’s pumped through a drinking water system, then it is treated as wastewater, and it’s put back into the river or the stream. Every time that happens, we gain probably around 30 milligrams per liter of chloride. We kind of laugh these days about water reuse. In California, it’s pretty common in Arizona, it’s pretty common, and people are like, “Oh my gosh, I would never reuse water.” Well, I hate to break it to them, but if you’re in any kind of a large water system, probably you’ve had water reuse. Think about it in terms of the Missouri River. The Missouri River obviously extends way into Montana, and cities begin using that water, drinking that water, treating that water, and putting it back into the Missouri River way up at the upper end of the reaches in Montana. So by the time it gets to Omaha, that water’s been used and reused dozens of times. If you assume that it’s been used ten times and it’s 30 milligrams per liter increase in regards to chlorides, every time it gets reused by the time it gets to Omaha, it would have a chloride residual somewhere in the neighborhood of about 300 milligrams per liter. We know because there are other streams coming into the river, that isn’t totally true because it gets diluted with the other water coming in. However, that is becoming a big deal, and we work with a lot of industries to try to help reduce the amount of chlorides that they’re having to release or treat. And it is not an option. Many states have begun instituting a real permit for chlorides, and there is a limit. It is not just a “Hey, this would be great to have this.”

Future Concerns with the Rise in New Technologies

Jeff Walters (27:11):

Thinking along the lines of best available technologies and trends, are there particular trends in the next 1, 3, 5, or 10 years that we think our clients are going to be facing that may cause an impact on their bottom line, to their production, to the survivability of their industry?

Chloride Limits

Darin Jacobs (27:33):

Well, I would say that the chloride is certainly concerning because, according to the EPA, there is no viable technology that is cost-effective to remove chloride from water. I would say that’s pretty true. You could use, for example, reverse osmosis, but then you get really, really clean water, and you get one side of the concentrate that is really, really, really dirty water that you have to get rid of. So it does not go away. The only way to really help with the chloride issue is don’t let it get in the water. And in many cases, for example, in a couple of our industrial partners, we’ve helped them change the way they treat their water internally to the plant. Instead of using salt-based zeolite water softeners, we’ve helped them move to reverse osmosis, so we’re no longer adding salt. And that was a significant reduction in chloride at the wastewater end of things, and that was a very effective way to make things happen and make it happen quickly.

Jeff Walters (28:34)

Maybe we should just tell people to quit brushing their teeth and spitting the stuff down the sink, Darin.

Darin Jacobs (28:38)

Well, the good news is that at least it isn’t too much chloride. It’s more fluoride, so not so bad. But you’re right, part of it is literally, what do we wash down the sink? And there are certain products that inherently have chloride as part of the product.

For example, and I’m going to make this up, but if you’re manufacturing hams in your facility, probably you have a lot of chloride because you have a lot of salt, and there is no way around that. That is part of the product. So, we have to look for other avenues to reduce the chloride, such as reusing brining solutions and reducing the salt used in water softening.

The other issue, of course, as we talked about earlier, is nutrient, which is the total nitrogen and total phosphorus also, which are very prevalent in food production. Phosphorus because of phosphoric acid cleaners. And as you know, every day, the plant has to be cleaned, and it has to be sterilized in every facility in every location. And phosphoric cleaners and acids tend to make a lot of phosphorus at the wastewater end. So oftentimes, we help by searching for other chemicals that can be used. In many cases, that simply doesn’t exist. It’s just inherent to the industry. So total nitrogen and total phosphorus treatment is really a big deal, and it’s going to become more and more of a big deal, and it’s many, many states where it will be a big deal.

Jeff Walters (30:10):

Shawn or Craig, any crystal ball futuristic issues that you’re seeing with your clients and their particular industries that are of concern or alarm in the next one, three to five years, or longer?

Continual Supply Chain Issues

Shawn Duke (30:22):

I think we kind of already touched on the supply chain issues. It’s the available labor market. That’s the struggle we’re seeing still. I think we’ll see for the next several years is how do we get a new established where we can have a better functioning supply chain so there are no delays in getting materials and how do we optimize that to help increase productivity so that we’re not struggling with the backlog of orders from different suppliers and manufacture clients especially. They are able to get their products out so they can finalize their sales. And I think I see that probably as the main issue they’re struggling with now, and I think we’ll see that for the next few years until we have an increase in more warehousing or changes to the suppliers or the shipping process.

Providing Results for Site Upgrades and Reconstruction of Existing Facilities

Jeff Walters (31:07):

We talked about how we are working day to day, or we’re designing for our clients, and we talked a little bit about site upgrades and reconstruction. Let’s go into a little bit more detail of what interactions do we have with the site upgrades and reconstructions of some existing facilities. What are some day-to-day tasks that our clients are asking for, and how do we provide results for them?

Rail Access Additions

Having immediate rail access is vital to industrial clients as it reduces the cost of cargo transportation.

Darin Jacobs (31:35):

Well, we’ve recently had more and more ask for either improved rail service or rail service from the start where they did not previously have it, and the rail service portion of this, really, I think is a much lower commodity cost for bulk commodities when it’s delivered by rail. A typical tank car may hold 30,000 gallons of liquid material, and the average on-the-road truck holds around 6,000 gallons. So for every rail car is probably about five truckloads. In many cases, it’s a cost-benefit. In many ways, it’s a delivery benefit. Much going back to Shawn’s discussion about the supply chain. A lot of these folks are building tank farms, and they’ll get rail cars, empty the cars into the tank farm, and they’ll keep the product onsite so they don’t have problems with running out of the product. When you couple that with many of the rail shippers are located at extreme distances, it makes a lot of sense to try to get that as a bulk commodity. Many of the customers we have are certainly looking at that as a benefit.

Warehousing & Storage

Shawn Duke (32:50):

Well, I’m seeing mainly has been a lot of need to add on to facilities for more warehousing or more outdoor yard storage. We’ve been looking a lot at how can we acquire additional space to store materials or the store the raw materials or store finished materials that are waiting on parts where we need to have a temporary storage facility where it’s not complete, but we can’t get the final pieces we need until a year from now. So we have to store as much as we can and then incorporate this into the process once we finally get that last part. Other than that, it mainly has just been additional storage facilities and additional warehousing.

Craig German (33:27):

Our work continues to be a mix from our clients’ needs of maintaining existing infrastructure, adding onto existing and new at this point, not really seeing a spike in one or the other.

Jeff Walters (33:42):

Okay. Well, I appreciate you three for talking with me today about industrial processes and how we can serve our industrial clients. If anyone who’s listening to this podcast has any questions or comments or would like to learn more about our firm, you can find us at our website, www.snyder-associates.com. Thank you.